How Stainless Steel Banding Helped

How Stainless Steel Banding Helped Reopen the San Francisco Bay Bridge

Author: It Straps On, Inc. – Thursday, October 10, 2013

When most people think of the San Francisco Bay, they picture the iconic Golden Gate Bridge. This bridge is arguably one of the most famous structures in the state, if not the entire country.

Earlier this month, however, another San Francisco bridge was revealed that could provide stiff competition.

This bridge, which reopened in early September, is the San Francisco-Oakland Bay Bridge. The newly renovated bridge finally opened to traffic on Monday, September 2, 2013.

ABC quoted the mayor of San Francisco, Ed Lee, who reportedly called the new bridge a “monument to creativity and ingenuity” and Loni Hancock, the state senator, who referred to the bridge as a “gorgeous piece of public art”.

The now breathtaking Bay Bridge does not have the happiest of histories. Achieving this innovative enhancement to the state’s infrastructure did not come without hardships and challenges.

Why Was it Necessary to Renovate the Bay Bridge?

It is fairly common knowledge that San Francisco is no stranger to earthquakes. This major city is located perilously close to the San Andreas Fault line, which constantly threatens to shake its foundation. In 1989, this is exactly what happened, and the Bay Bridge suffered significant damage.

The damage caused to the bridge had major ramifications on the city. Tragically, this event did cost the life of a motorist that was crossing the Bay Bridge. The closing of the bridge for repairs also had a major impact on the city’s economy. As CBS News explains, approximately 250,000 commuters cross this bridge on any given workday, currently.

Construction Begins on the Eastern Span

The San Francisco-Oakland Bay Bridge is divided into two major spans. The western span has received minor renovations and has generally been in better condition than the eastern span.

The eastern span was also home to what has been referred to as the “dreaded S-curve”. As The Atlantic Cities explains, this notorious curve, which was a sharp-angled curve that led drivers into the Yerba Buena Island Tunnel, is a place where many people have experienced accidents over the years. This S-curve was one of the first things to go during the renovation.

The Long Journey that Led to a Beautiful and Safe Bridge

In 2002, the Bay Bridge renovation began, and by 2013 it became the most expensive public works project in the history of California, according to the NY Daily News.

One of the reasons that the restoring project has taken so long, and required so many resources, is because the city aimed to create a bridge that would remain stable in the face of an earthquake. This is no easy task. The architects and construction crews faced many challenges, and many of the construction materials would not hold up when earthquake pressures and stresses were simulated.

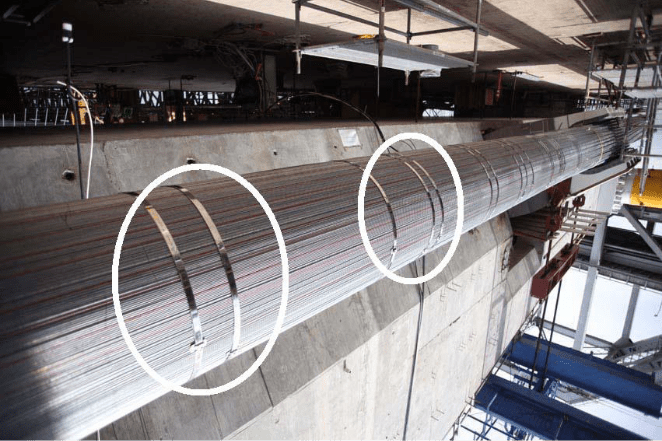

The NY Daily News also reported that one of the strategies architects used to strengthen the foundation was to install reinforced steel pilings 300 feet deep into the Bay floor. According to NPR, a cable that contains 137 strands of banded steel also provides support for the bridge.

Enter the Stainless Steel Banding

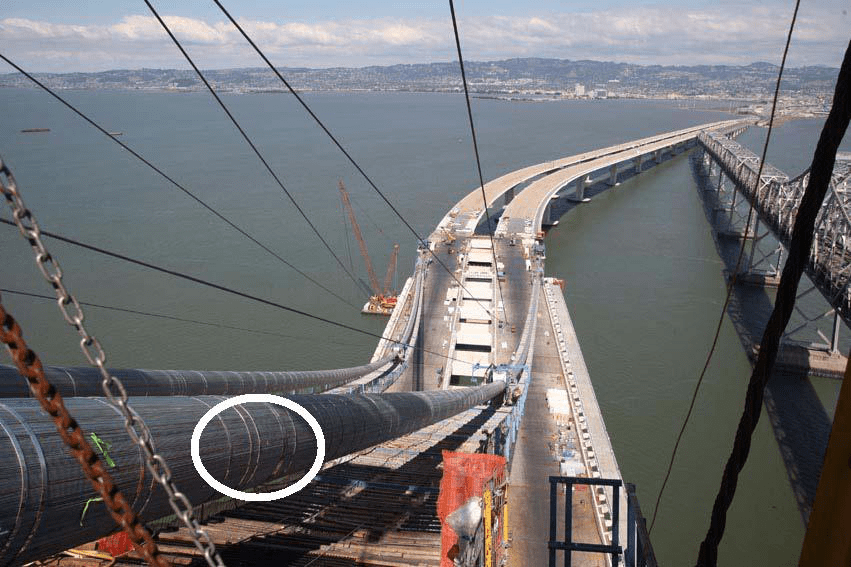

The bridge contains multiple cable systems that span numerous directions. As reported by CBS San Francisco, these steel strands contain roughly 48,000 LED bulbs, illuminating a veil of steel strands to drivers as they emerge from the tunnel onto the bridge.

This is where stainless steel banding comes in. As you can see from the photos in this post, there are many places where banding was used to secure these heavy loads and provide the ultimate in strength and stability.

Thanks to the help of reinforced steel, stainless steel banding, and incredibly creative and innovative architects and construction crews, many people would agree that San Francisco was able to fulfill its promise of opening a beautiful and durable bridge.