The Stainless Steel Banding Guide:

Everything You Wanted to Know About

Stainless Steel Banding – In One Place!

Do you need to replace old or broken street sign brackets? Do you need to strap down insulation or metal pipes and get them to stay even in a tough environment? Or are you looking for something to secure steel cabling together for a bridge or underground drilling project?

For these jobs and many others, when the plastic or poly just won’t do, what you need is stainless steel banding.

If you’re in the market for stainless steel banding, our guide is just what you need. It covers everything from what type of steel to look for, what types of alloys are available to choose from, what tools you’ll need and even what to look for in a vendor.

What Is Stainless Steel Banding?

Stainless steel banding is steel with alloys that are different widths and thicknesses that can then be used to encircle various objects. It’s like using stainless steel as a belt to attach one object to another or make a stack of items stay in place. This type of banding is used across a number of industries, so there’s a good chance your business could benefit from learning more about it as well.

Different Alloys of Steel Banding

Just like about any other kind of material, there are different types of steel, called alloys. When it comes to stainless steel banding, there are generally only three worth considering.

These are:

Choosing the right band is essential to getting the results you need, so let’s take a moment to look into each one.

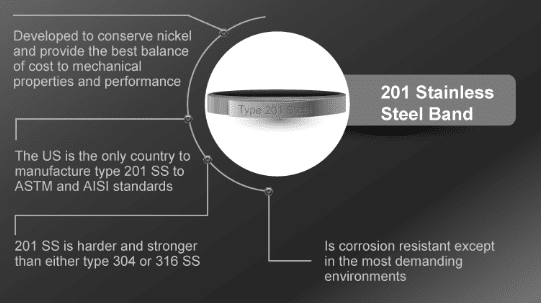

Type 201

Type 201 is going to be the most affordable option, largely because it’s made with so much manganese instead of nickel (though some of the latter is present). This is probably one of the main reasons it is the industry standard. Between Types 201 and 304, the former is definitely the harder and stronger version.

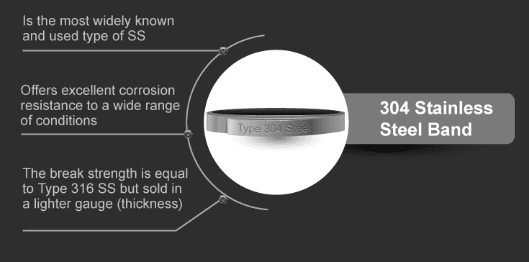

Type 304

Speaking of which, Type 304 has plenty to offer too. It’s far more corrosion resistant than Type 201 is, which is why you’ll find it being used by all sorts of businesses that work in environments where moisture, salt, and other threats are constantly working against the metal. Type 304 is a great choice for attaching lightweight signs to metal poles, fastening insulation to pipes, and much more.

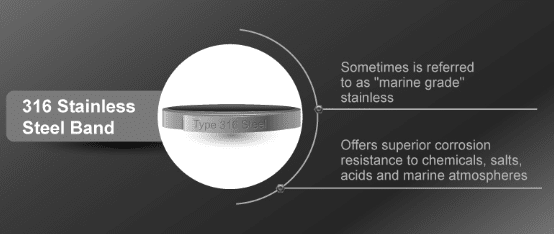

Type 316

Type 316 is going to be the most expensive form of steel available, but it’s also the most resistant to corrosion. This metal is also great about standing up to extreme temperatures. It’s these two factors that make Type 316 popular on oil rigs and on machines that go underwater.

Always Choose American Steel

No matter what kind of alloy you deem best for your needs, don’t be surprised to find distributors of it all over the world. However, you’ll be best off ensuring that the kind you go with was made in America. Also be aware that just because you’re dealing with an American distributor it doesn’t necessarily mean that’s where their metal is from.

America has the highest standards for manufacturing and quality in the steel industry, which is why it’s so important to make sure your banding was made in the U.S. Have the distributor confirm as much before ordering and don’t be afraid to ask for the Certification from the steel factory.

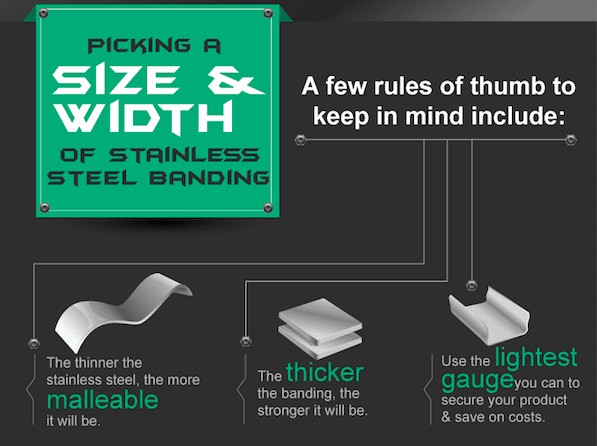

The Size and Width of Your Banding

Stainless steel banding comes in a wide range of sizes and shapes. This is why it can be used for so many different applications. Across the three main types of alloys we mentioned earlier, the sizes generally run from ¼ to two inches wide and from .015 to .044 in terms of thickness.

As you can probably imagine, the thicker the steel banding, the stronger it’s going to be and the more pressure it can stand from the items it’s binding.

However, those qualities come at a price. First of all, this much strength will be hard to work with. Bending a thick slab of steel is never going to be easy. You have to be especially careful about choosing the correct product for your application and then using the correct tool to apply it.

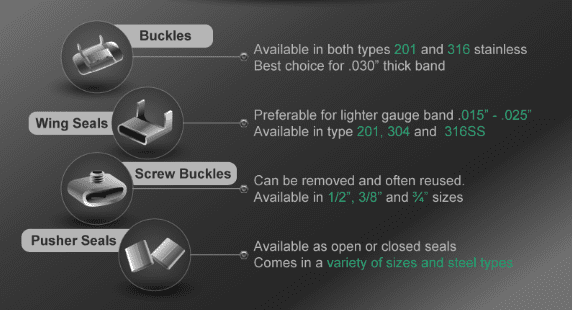

The Necessity of Closures

By itself, no stainless steel band is going to do you much good. After all, it’s not like you’re going to tie the band together like you would with a ribbon or a rope. Instead, you need what’s called a closure to “close the circle” around the object. Obviously, this is an important job, meaning you should take your time choosing the right closure device.

There are four main types of closures:

Tools for Using Stainless Steel Banding

As we mentioned above, stainless steel banding isn’t always the easiest thing to work with. However, if you have the right tools for the job, it doesn’t have to be so much of a challenge.

The three main types of tools you’ll need are:

- Cutting Tools:

- Tensioning Tools:

- Crimping Tools:

These are obviously the tools you need to cut steel banding. The exact kind you need will depend on the type of banding you’re using. Heavy-duty steel is going to need equally heavy-duty cutting tools. You’ll need to cut your banding once when you get enough of it for the job and then probably once more after you’ve applied closure if you find there is excess banding hanging off.

Applying a closure also means applying tension. That’s how you get the banding nice and tight. Without this tool, the amount of tension necessary would be all-but-impossible for a person to bring about on their own.

Crimping tools are necessary when using pusher seals.

Choosing the Right Vendor

Even with all the above in mind, you need to make sure you’re getting your stainless steel banding from the right company. Like we said, be sure they carry American steel. However, you should also make sure they have enough in their inventory on a regular basis to meet the demands your company has.

Furthermore, check to confirm they ship your order immediately or no later than a day after you place it.

This may seem like a lot of information, but the truth is that stainless steel banding is actually fairly easy to understand and apply. Once you begin working with it, a lot of the above will make more sense, and you’ll become more confident in all the minute details.